The work should be executed as quickly as possible due to work hardening characteristics of stainless steels and a degree of over bending is necessary to counteract the springback of the bend.

Bending stainless steel flat bar.

Bending the metal when the area along the line is bright orange turn off the torch and set it aside.

Due to work hardening bending should be done quickly.

Bending flat material and bars flat sheet plate and bar products can be bent using the press brake or bending machine.

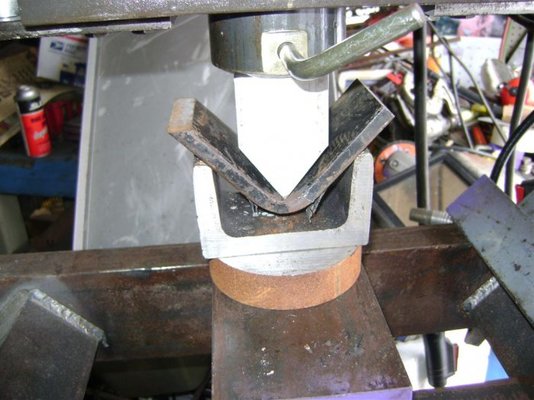

When you bend a stainless steel rod mechanically with a press brake you create a bend that has a true radius.

Brush off scale at the bend with a wire brush.

Press straight down with one hand on the end of the metal applying uniform firm pressure to bend it on the line left.

If doing a big bend i would heat with a torch first.

Of the two ways heating the stainless steel rod is the most commonly used way to.

However it does work harden so large bends and repeated bending can cause cracking.

A cold rolled bar is shinier than a hot rolled bar but is also harder to bend.

This makes bending stainless steel with common hand tools difficult and a sheet metal brake is often required although one technique to bend stainless steel using hand tools works well on shorter length bends.

If you do not have access to a press brake your other option is to use an oxy acetylene torch to heat the rod and then bend the heated area of the rod.

Choose the right steel alloy.

Bending it could would work harden it and strengthen it substantially.

The stronger the steel the more the bend will approximate a v while the weaker the steel the more the bend will look like a u.

304 is a relatively ductile stainless and will bend to some degree.

If it didn t break from the tight radius of the bend.

Some over bending will be required to counteract spring back of the bend.

Most steel bars are either hot rolled or cold rolled.

I think dimensions wise your bending brake will work but i don t know if it will be able to put a clean sharp bend in 3 16 bar you think.

Anyway 304 is an austenitic stainless steel so it shouldn t lose any strength from the heating.

Stainless steel is even harder to bend.